This project is a MIDI-capable accordion-style controller with a fully 3D-printed body. Button accordions in the US are very rare, and when found, cost a minimum of $1000— at least $2000 for digital models. The goal of this project was to create the absolute cheapest digital accordion possible.

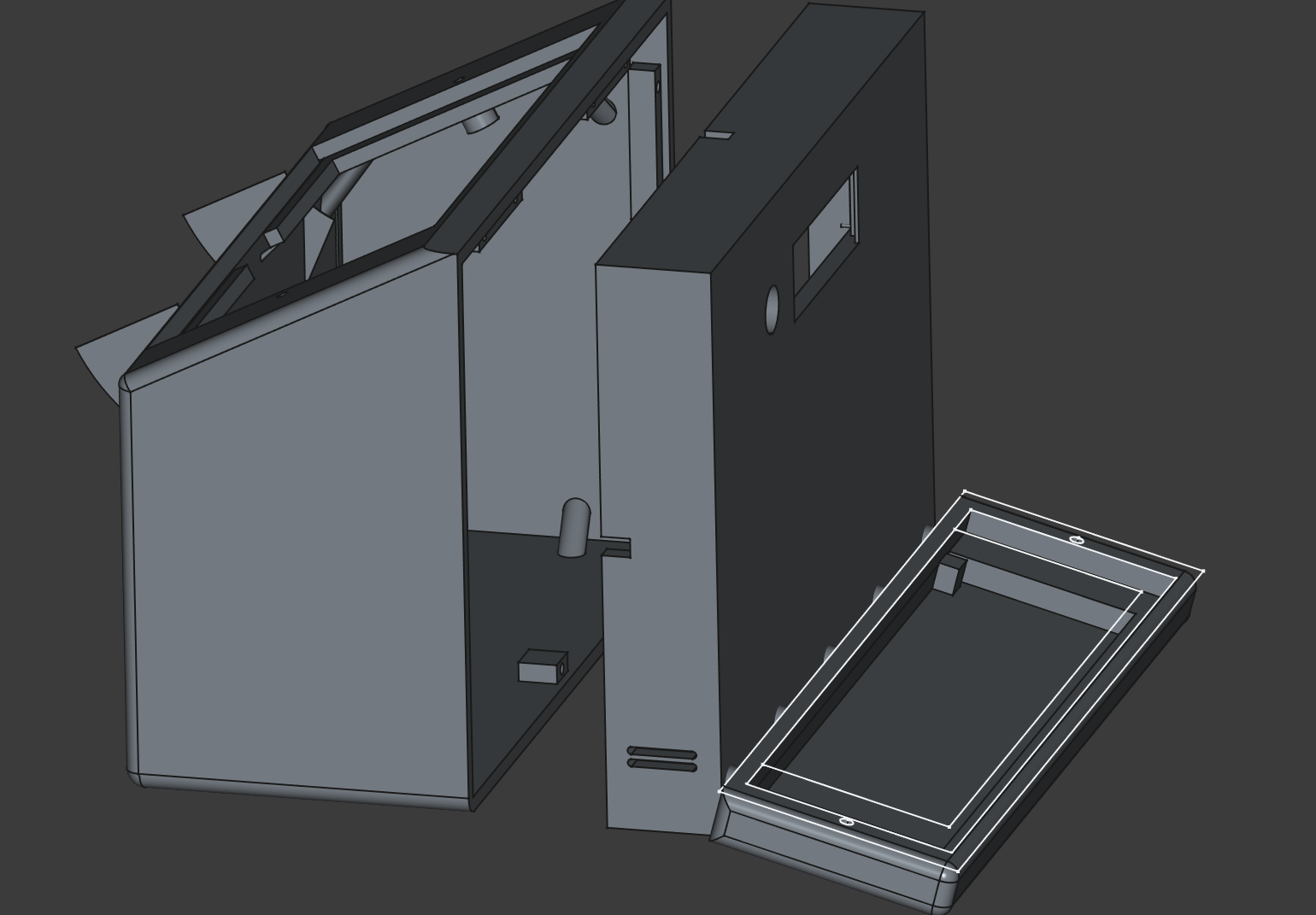

The body is printed entirely of PLA and TPU using an entry-level 3D printer. Everything is soldered by hand, including a custom-designed circuit board. This first iteration has over 100 buttons. Common microcontrollers like the ESP32 only enable around 20–30 input signals. Even after wiring the buttons in a matrix, more pins are needed than available—especially when scaling to a larger accordion in the future.

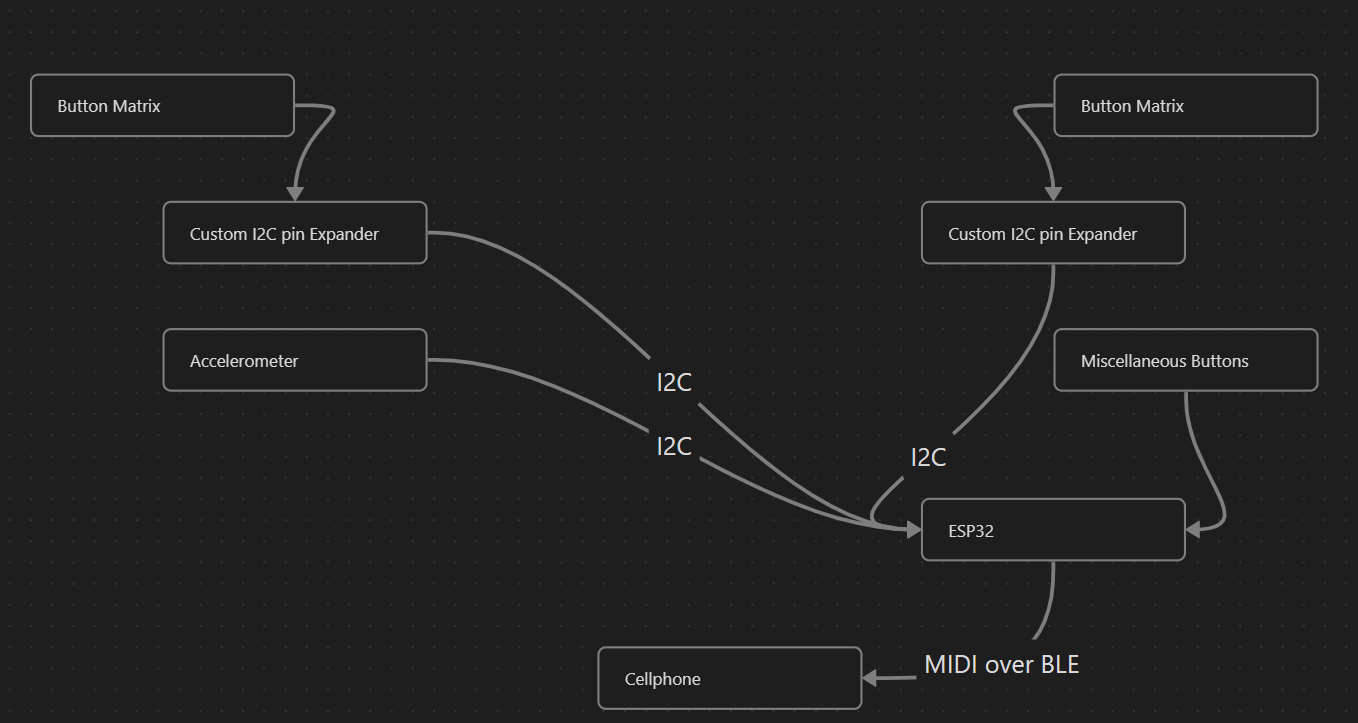

Instead of onboard sound processing, I decided to transmit button and sensor states over Bluetooth and use a cellphone to process the audio.

Process Summary

This schematic shows the basic idea.

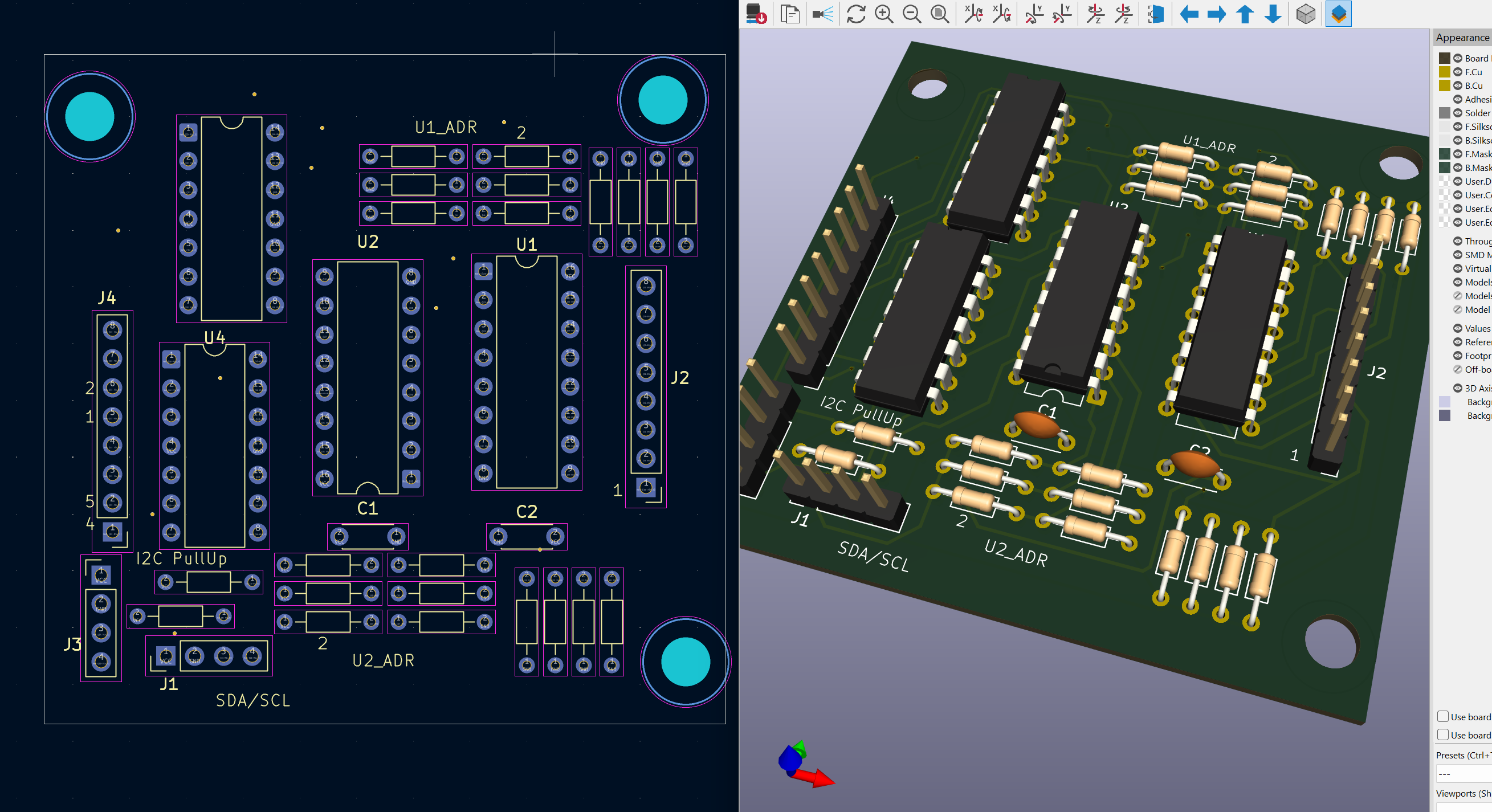

I designed this circuit layout and had it fabricated for around $4–15 depending on shipping, plus $1–2 for components from Chinese sources. It uses I2C GPIO bus expanders and op-amps to boost current for the microcontroller. More expensive expanders wouldn’t need op-amps, but this solution is cheaper.

I learned 3D modeling specifically for this project. Here’s a model fragment.

Video demo coming soon.

Tools: FreeCAD, ESP32, C/C++, KiCAD, 3D printing

← Back to portfolio